Basic Info.

Model NO.

AAAAA---CAN----001

Carbide Grades Available

Yg6 Yg8 Yg6X Yg10X

Keywords

Carbide Parts

Surface

High Polished

Performance

High Corrosion Resistance

Bending Strengthbending Strength

More Than 400 MPa

Fracture Toughness

4.5-7.0 MPa.M1/2

Transport Package

Standard Packing for Cemented Carbide Nozzles

Specification

customized

Trademark

RYDMET CARBIDE

Origin

China

HS Code

82090030

Product Description

Rydmet Customized Cemented Tungsten Carbide Alloy Oil Nozzle for Oil Gas Mining Industry:

Thanks to so many years of experience and the high accuracy of our machines, we are now almost able to make any types of Carbide Components ( wear Parts) we meet, they have started to reply on Rydmet Carbide's Carbide Wear Comnponents and Wear Parts.

The Carbide Nozzles we make are divided into standard nozzle, medium long nozzle, micro long nozzle, pulse nozzle and center nozzle for tri-cone bit, single cone nozzle, diamond bit nozzle and the like for single cone bit, etc.

Rydmet cemented carbide nozzles shows high wear and abrasion resistance helping to maintain a longer tool life

We also make the Carbide irregular carbide Nozzles as per our clients requirment.

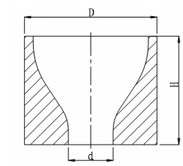

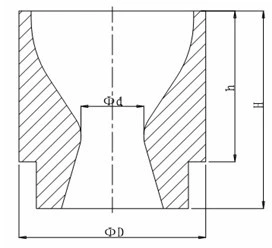

The Common type of Carbide Nozzles for PDC Drill Bits

| Drill Bit Inner Diameter (mm) | 95.2-120.6 | 142.9-171.4 | 190.5-200.0 | 212.7-349.2 | 374.6-660.4 | Nozzle Diameter (mm) |

| (3 3/4-4 3/4) | (5 5/8-6 3/4) | (7 1/2-7 7/8) | (8 3/8-13 3/4) | (14 3/4-26) | ||

| Drill Bit Outer Diameter (mm) | 20.3 | 23.5 | 29.74 | 32.89 | 40.84 | |

| Assembly Length | 17.48 | 19.05 | 20.62 | 26.97 | 26.97 | |

| H(mm) | ||||||

| Carbide NozzleTypes | S1-6 | S2-6 | S3-6 | S4-6 | S5-6 | 6.35 |

| S1-7 | S2-7 | S3-7 | S4-7 | S5-7 | 7.14 | |

| S1-8 | S2-8 | S3-8 | S4-8 | S5-8 | 7.92 | |

| S1-9 | S2-9 | S3-9 | S4-9 | S5-9 | 8.74 | |

| S1-10 | S2-10 | S3-10 | S4-10 | S5-10 | 9.53 | |

| S1-10A | S2-10A | S3-10A | S4-10A | S5-10A | 10.31 | |

| S1-11 | S2-11 | S3-11 | S4-11 | S5-11 | 11.13 | |

| S1-12 | S2-12 | S3-12 | S4-12 | S5-12 | 11.91 | |

| S1-13 | S2-13 | S3-13 | S4-13 | S5-13 | 12.7 | |

| S1-13A | S2-13A | S3-13A | S4-13A | S5-13A | 13.49 | |

| S1-14 | S2-14 | S3-14 | S4-14 | S5-14 | 14.27 | |

| S2-15 | S3-15 | S4-15 | S5-15 | 15.08 | ||

| S2-16 | S3-16 | S4-16 | S5-16 | 15.88 | ||

| S2-17 | S3-17 | S4-17 | S5-17 | 17 | ||

| S2-17A | S3-17A | S4-17A | S5-17A | 17.48 | ||

| S2-18 | S3-18 | S4-18 | S5-18 | 18.25 | ||

| S3-19 | S4-19 | S5-19 | 19.05 | |||

| S3-20 | S4-20 | S5-20 | 19.84 | |||

| S3-20A | S4-20A | S5-20A | 20.64 | |||

| S3-21 | S4-21 | S5-21 | 21 | |||

| S3-22 | S4-22 | S5-22 | 22.23 | |||

| S4-23 | S5-23 | 23.01 | ||||

| S4-24 | S5-24 | 23.81 | ||||

| S4-25 | S5-25 | 25.4 | ||||

| S4-26 | S5-26 | 26.19 |

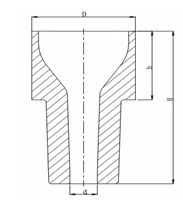

The Long Throat type of Carbide Nozzles

| type of cone bit(mm) | 190.5-200.0(7 1/2 7/8) | 212.7-349.2(838-133/4) | 374.6-660.4(1434-26) | nozzle Recess dis (mm) |

| nozzle O.D.(mm) | 29.74 | 32.89 | 40.84 | |

| Assemble Length(mm) | 20.62 | 26.97 | 26.97 | |

| type of nozzle | S603-6 | S604-6 | S605-6 | 6.35 |

| S603-7 | S604-7 | S605-7 | 7.14 | |

| S603-8 | S604-8 | S605-8 | 7.92 | |

| S603-9 | S604-9 | S605-9 | 8.74 | |

| S603-10 | S604-10 | S605-10 | 9.53 | |

| S603-10A | S604-10A | S605-10A | 10.31 | |

| S603-11 | S604-11 | S605-11 | 11.13 | |

| S603-12 | S604-12 | S605-12 | 11.91 | |

| S603-13 | S604-13 | S605-13 | 12.70 | |

| S603-13A | S604-13A | S605-13A | 13.49 | |

| S603-14 | S604-14 | S605-14 | 14.27 | |

| S604-15 | S605-15 | 15.08 | ||

| S604-16 | S605-16 | 15.88 | ||

| S605-17 | 17.00 | |||

| S605-17A | 17.48 | |||

| S605-18 | 18.25 |

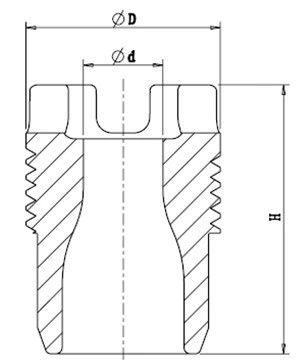

The Threaded Carbide Nozzles for PDC Drill Bits

| Nozzle O.D ( mm) | 25.021 | Nozzle Recess Dia(mm) |

| Assemble length (mm) | 34.8 | |

| Type of Nozzles | SD-08 | 6.35 |

| SD-09 | 7.14 | |

| SD-10 | 7.92 | |

| SD-11 | 8.74 | |

| SD-12 | 9.53 | |

| SD-13 | 10.31 | |

| SD-14 | 11.13 | |

| SD-15 | 11.91 | |

| SD-16 | 12.7 | |

| SD-17 | 13.49 | |

| SD-18 | 14.27 | |

| SD-19 | 15.08 | |

| SD-20 | 15.88 | |

| SD-21 | 16.67 | |

| SD-22 | 17.46 |

The Central Carbide Nozzles for PDC Drill Bits

| Type of Cone bit (mm) | 8 3/8-13 3/4 | 11 5/8-17 1/2 | Recess dia (mm) |

| Nozzle O.D. (mm) | 23.5 | 32.89 | |

| Assemble Length (mm) | 19.05 | 26.97 | |

| Type of nazzle | SC2-10 | SC4-10 | 9.53 |

| SC2-11 | SC4-11 | 11.11 | |

| SC2-12 | SC4-12 | 11.91 | |

| SC2-13 | SC4-13 | 12.7 | |

| SC2-14 | SC4-14 | 14.27 | |

| SC4-16 | 15.88 |

Recommend Grade: RD11C RD11M

| Rydmet Standard Carbide Grade Chart for Wear Parts, Components | ||||||

| Grade Code | Binder Content & Type | Hardness (Ra) | Hardness | Density (g/cm3) | Transverse Rupture Strength (TRS) | Grain Size |

| (HV30) | ||||||

| RD06X | 6% Co | 91.5 | 1530 | 14.95 | 2,300 | Fine |

| RD08X | 8% Co | 90.8 | 1450 | 14.75 | 2,500 | Fine |

| RD15X | 15% Co | 88.9 | 1250 | 13.9 | 2,700 | Fine |

| RD06M | 6% Co | 90.3 | 1380 | 14.95 | 2500 | Medium |

| RD08M | 8% Co | 89.5 | 1300 | 14.75 | 2600 | Medium |

| RD011M | 11% Co | 89.2 | 1270 | 14.3 | 2,650 | Medium |

| RD015M | 15% Co | 87 | 1070 | 14.0 | 2,650 | Medium |

| RD06S | 6% Co | 93 | 1790 | 14.95 | 2,600 | Submicron |

| RD10S | 10% Co | 91.8 | 1580 | 14.45 | 2,650 | Submicron |

| RD10C | 10% Co | 88 | 1160 | 14.5 | 2,700 | Coarse |

| FC11C | 11% Co | 87.5 | 1110 | 14.45 | 2,800 | Coarse |

| RD06N | 6% Ni | 90 | 1350 | 14.9 | 1,800 | Medium |

| RD08N | 8% Ni | 88.5 | 1700 | 14.7 | 1,900 | Medium |

| RD10N | 10% Ni | 88 | 1160 | 14.5 | 1,930 | Medium |

| RD12N | 12% Ni | 87.5 | 1110 | 14.1 | 1,950 | Medium |

| RD06N2 | 6% Ni+Cr | 89 | 1250 | 14.2-14.9 | 1,600 | Medium |

| RD08N2 | 8% Ni+Cr | 88.5 | 1210 | 14.0-14.8 | 1,700 | Medium |

| RD06UF | 6% Co | 94 | 2010 | 14.9 | 3,800 | Ultra-fine |

For any inquiry or Qeustion, please don't hesitate to contact us, our skilled and expreienced Team are willig to help you always!