- Overview

- Product Description

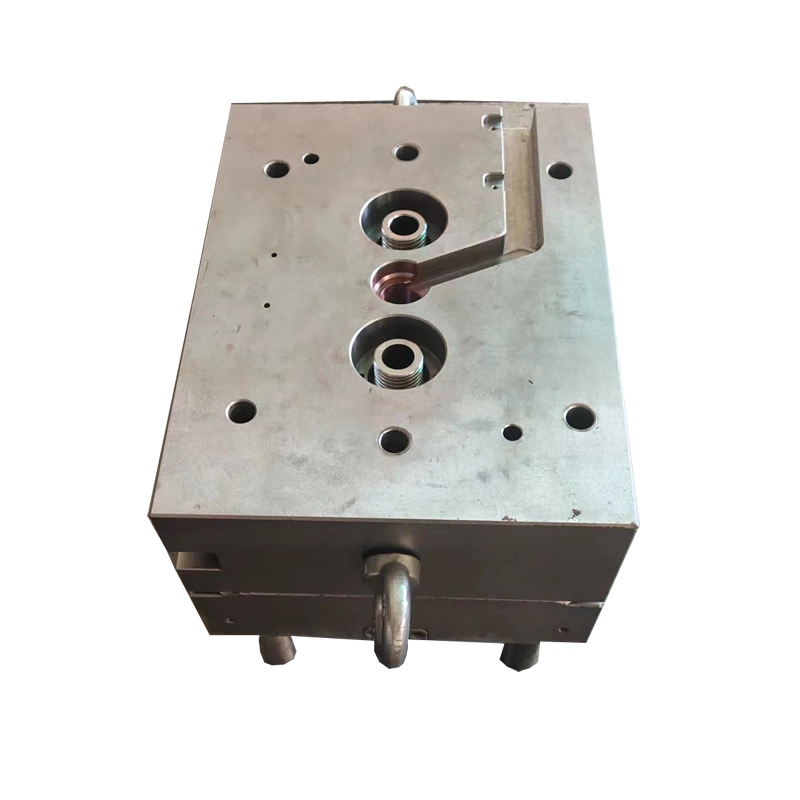

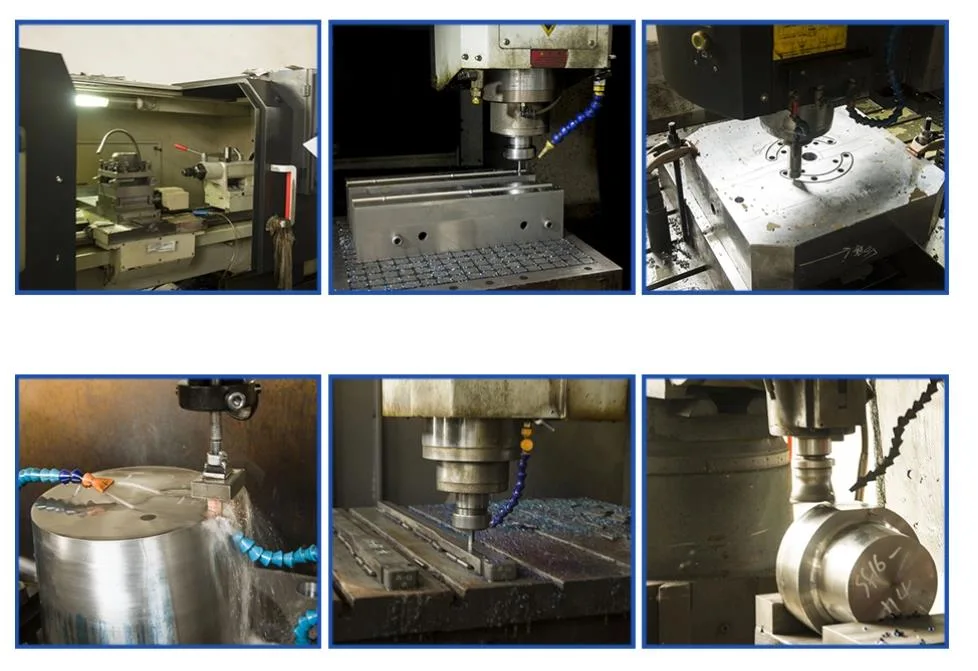

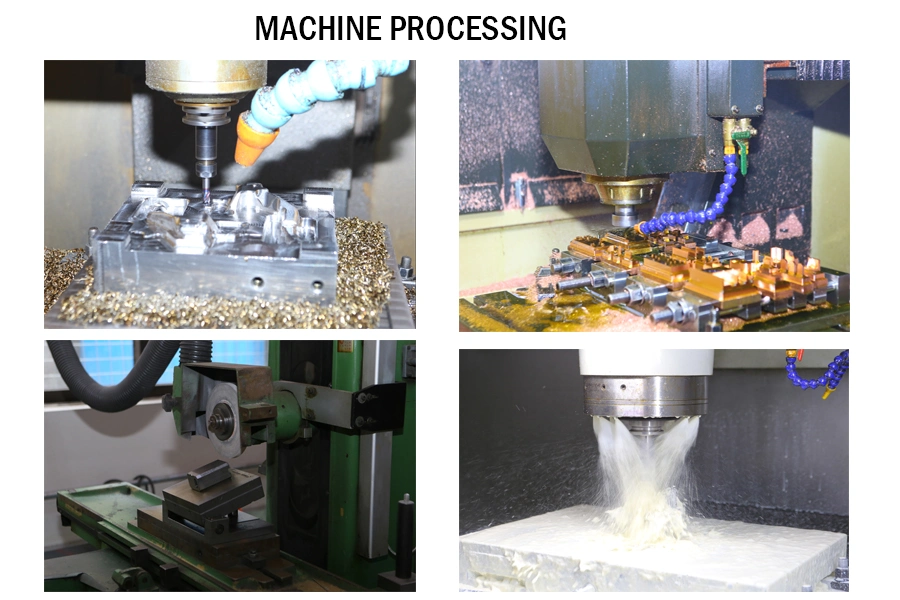

- Detailed Photos

- Other Products

- Quality Control

- Company Profile

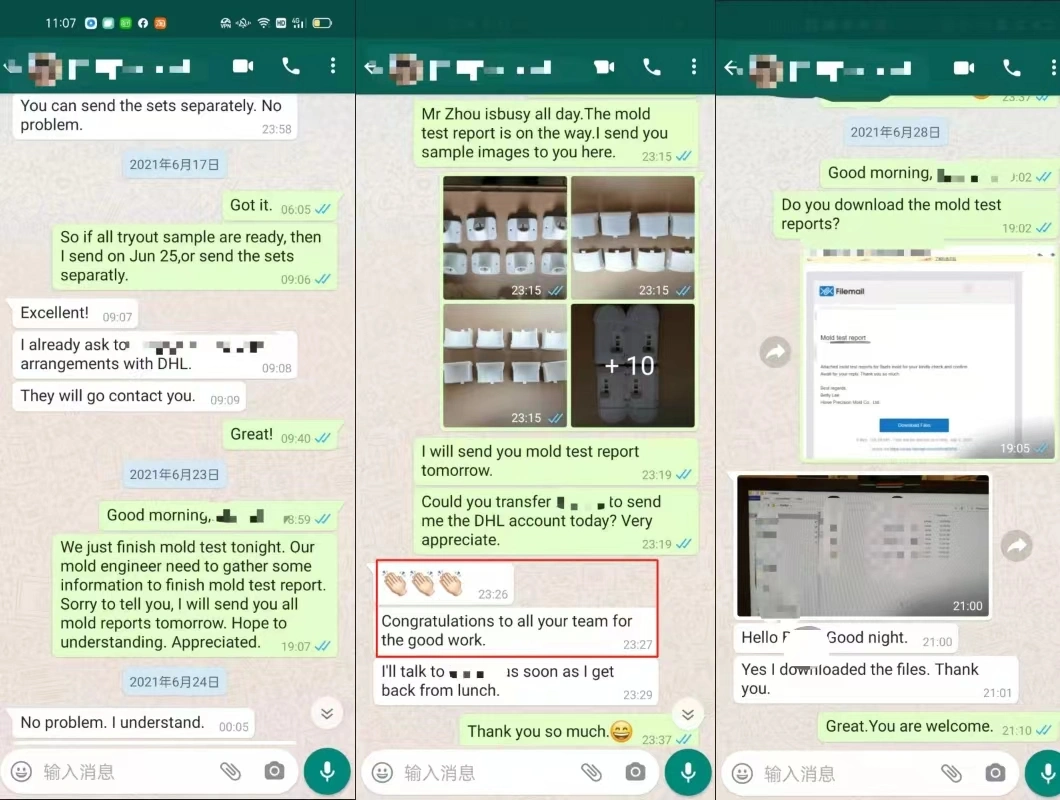

- Customer Feedback

- Business Partner

Basic Info.

Packaging & Delivery

Product Description

| Name | Factory Supply Plastic Injection Mold For PBT Electronic Parts |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Mold base | LKM 50 standard mould base or Self-made |

| Mold runner | Hot/Cold Runner |

| Base material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9 ,SKH-51,M35,M42,ASP23 |

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc |

| Diameter | 5-1000mm,or customized |

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, PMMA,PVC,TPE,TPU etc |

| Color | White,black,green,nature,blue,yellow,etc |

| Treatment | S45C Pretreat>25Hrc,And Nitriding |

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Shape | Sheet, rod, tube, gear, pulley, guide rail, or as per your drawing |

| Ejection system | Stripper plate,Lifter,Push bar,Ejection pin etc |

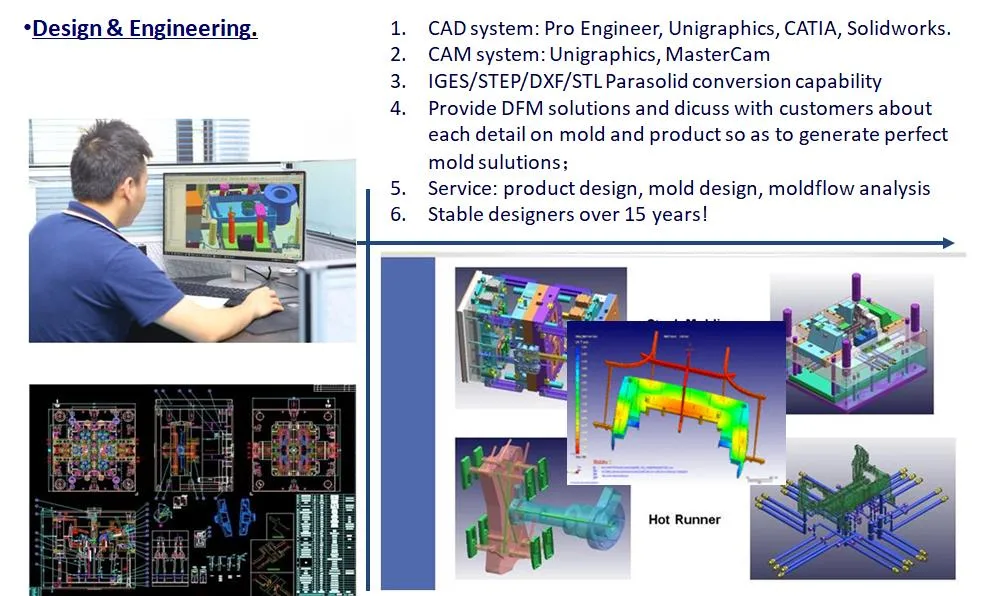

| Design software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad |

| Mold of steel suppliers | FINKL,Assab,DAIDO,LKM,Buderus |

| Hot Runners suppliers | Synventive,YUDO,INCOE,HASCO,DME,MOLDMASTER,HRS,DELACHAUX,SINO |

| Certification | ISO9001,SGS,Test Report,RoHS |

| Lifetime | >300 Thousand Times |

| Shipping Packing | Wood case or carton box 1. With plastic bag, with pearl-cotton package 2. To be packed in cartons or wood case 3. Use glass tape to seal cartons, or pin tight the wood case with nails. 4. Deliver out by DHL, FEDEX Or according to the customer's requirement. |

| Lead time of first samples | Around 4~7weeks |

| Other | 24 hours instant and comfortable customer service. |

| Shipping status notification during delivery. | |

| Rhipping status notification during delivery. |

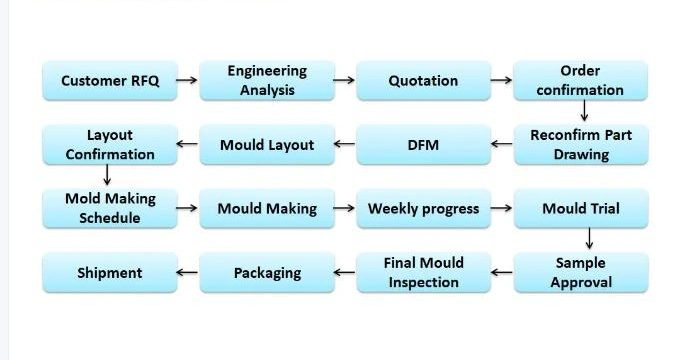

How to order from HOWE?

1. Inquiry-Professional quotation.

2. Confirm the price. lead time. artwork. payment term etc.

3. Howe sales send the Proforma Invoice with Howe company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5.Initial Production Stage-Inform the clients that we have got the payment and will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time.

6. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.

7. End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party Inspection .

8. Client make payment for balance and Howe ship the cargo. Also Howe can accept payment term-Balance against TT,Paypal or D/P payment Term.

9. Order can be say "finish" when you receive the goods and satisfy with them .

10. Feedback to Howe about Quality. Service. Market Feedback & Suggestion. And we can do better .

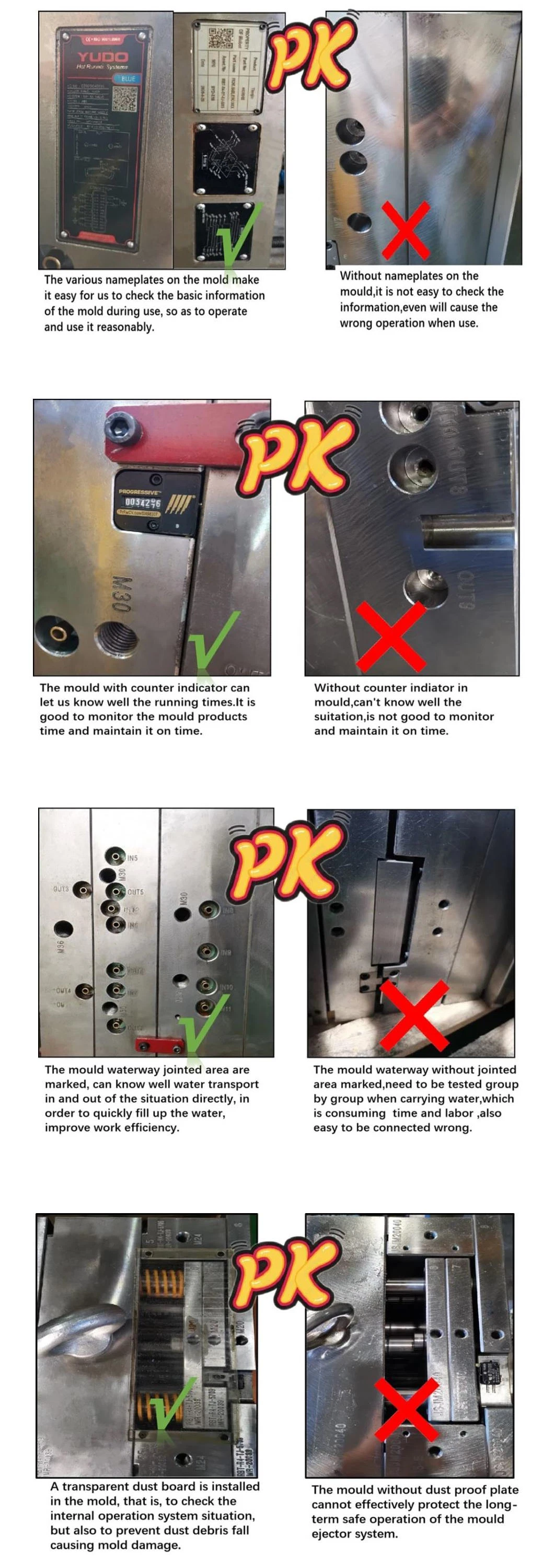

Howe Mould Quality Control

1.Mould Material Q/C

a) mould steel checking (hardness,flaw detection)

b) mould spare parts checking (hardness,size)

2.Mould Making Process Q/C

a) design checking ( part design,mould design,mould engineering drawing)

b) mould size checking (according to drawing)

c) mould testing (check mould working,sample)

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1. Custom Plastic Injection Parts

2. Multi-cavity plastic parts

3. High Precision Molds

4. Insert & over molding

5. Double Shot Mold(2K mold)

6. Unscrewing Molding

7. Gas-assisted Molding

8. Die Casting Molding

9. Prototype plastic parts and Low cycle plastic parts molding

10. Gas Assist molding

11. Elastomeric molding

12. IML & IMD part production

13. Thin wall plastic molding

14. High temperature molding

Dear Customer,

We have more than 12 years experience in making plastic mold& die casting mold.

Our products have TUV ,SGS& ISO9001 Certification.

If you have any demand on our products, contact me free.